Or is it more nuanced, like "yes for simple things like a radiator, no for a pump".

I kinda glossed over t his in my previous reply. To expand slightly:

The process of making radiators involved a fair amount of soldering, cutting holes / threads, and lastly painting.

The end product is therefore likely to have bits of swarf, flux residue and whatever else inside. You can also have secondary issues like the threads being gummed with paint, the holes being slightly misspaced for the fans, etc. There's also design considerations, like does the rad have a bleed port, or plates to stop you puncturing the lamellae with over-long machine screws.

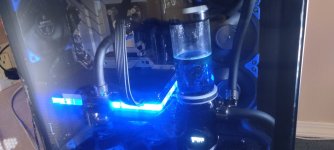

I used a diluted solution of brick acid (used for removing mortar stains) in hot tap water to flush out the rads in my current build, mainly because I had it to hand and it's a cheap source of hydrochloric acid. I followed that with hot tap water, then DI water, before draining and filling with a clear coolant pre-mix. Almost nothing came out to be honest, but I wanted to be sure. Nearly five years on, no problems to report. It might have been moot because they are HWL rads and they have a decent rep for being pretty clean, since they are made well and apparently get a flush during factory production. But you can see how that sort of thing would be the first to go if you were looking to bring down production costs.

Likewise with the fan holes, if they're a mm or two out it's not catastrophic, you might have to finagle the fans on there and be sure to only tighten the screws down when all the threads are attached. So for something relatively simple like a rad, as long as it doesn't leak, you can usually work around any issues. Even if it did leak you can often repair the leak with solder, if it's a copper rad.

For pumps, I tend to stick with the Laing D5. It's almost certainly overkill for most loops but you can get a Vario version, set it to speed #2 (out of 5) and forget about it. There's lots of other DC pumps out there, and some of them are probably fine, but it's so hit and miss I wouldn't bother. The D5's weakness is being run dry, so while I have had decent luck with second hand D5s on eBay, if there's any wear on the ceramic bearing face then run a mile. If they don't show pictures of it, ask for them. I mention it because the D5 is a pricey thing to buy new and assuming it's not been maltreated, a second hand one will still most likely have years of life in it. I managed to pick up a decent one for £25 for the loop in my boys' PC, they go for £75 or more new in the UK.

CPU blocks are also a decent shout if you can find one that fits your socket. They are usually pretty easy to disassemble (and clean if needed). Both my systems are running second hand blocks. You can also get very cheap CPU blocks on Amazon and AliExpress and while they probably won't perform quite as well as the best "branded" blocks, they will be very nearly as good, you just need to check the gasket is properly installed etc, since again the QC on these things is going to be minimal.

Your GPU block will likely be the most expensive single item in the whole damn loop, due to the semi-custom nature of these things and the amount of copper and machining involved. But if you're doing a custom loop and not cooling your GPU, then you're wasting your time and money really. My 1080Ti I bought second hand when the 2XXX series had just been announced, and it already had an EKWB block fitted by the original purchaser. The 3080Ti in my main rig has a Watercool.de block which I fitted myself, a buttock-clenching experience if ever there was one. You can get GPUs that are already fitted with a block but the premium for this is often ludicrous. The benefit is that it's pretty much plug and play, and you don't have any concerns about the block not fitting. Not every GPU out there will automatically get a block that will fit it, so you have to be a bit careful when choosing, double check compatibility charts, etc. I bought a Zotac card because it was cheap and had been confirmed by Watercool to fit one of their generic 3080Ti blocks. The cooler was known to be noisy and the power stages weren't the absolute best, but because I knew I would be removing the air cooler and cooling the MOSFETs with water, it didn't matter.